Finishing Services in Minnesota

Engineered Finishing Inc. is a trusted name when it comes to the best finishing services in Minnesota. Since its inception, EFI has served a wide range of industries. We are committed to quality and customer satisfaction when offering industrial finishing services.

Backed by years of experience, we are capable of handling finishing jobs irrespective of their size. This means we can process small to large quantities within a given time. Our experts apply their vast knowledge and finishing experience while handling every project.

We offer high quality, efficient, and affordable finishing services in MN including Blasting, Vibratory, and Hand Deburr. Our finishing solutions are second to none.

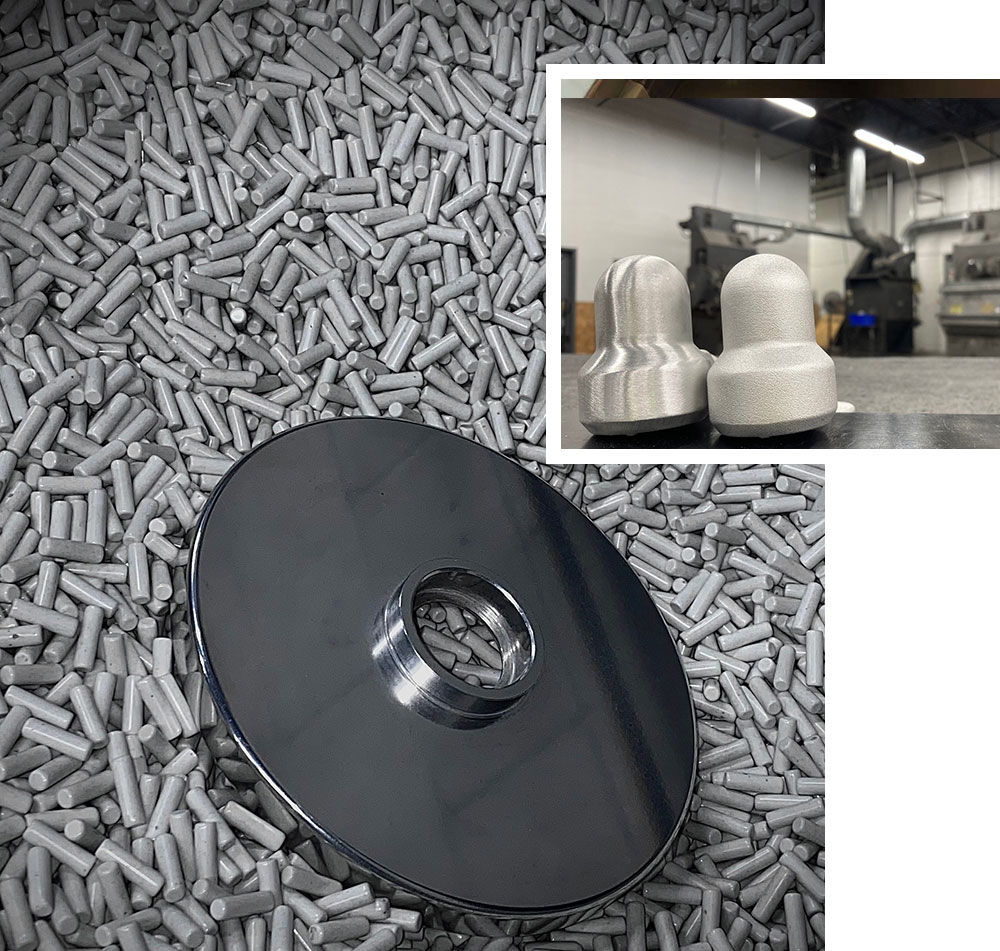

Blasting

Blasting is a viable solution when you need to remove, deburr, or deflash metal parts. This process also helps to enhance the surface texture for better adhesion.

Our blasting services include:

These processes can effectively remove burrs and loose flash from the parts. Usually, blasting proves to be effective while removing die-casting marks.

When offering finishing services in Minnesota through blasting, we use both glass and ceramic beads as efficient media. In addition, plastic or aluminum oxide media is also used depending on the requirement.

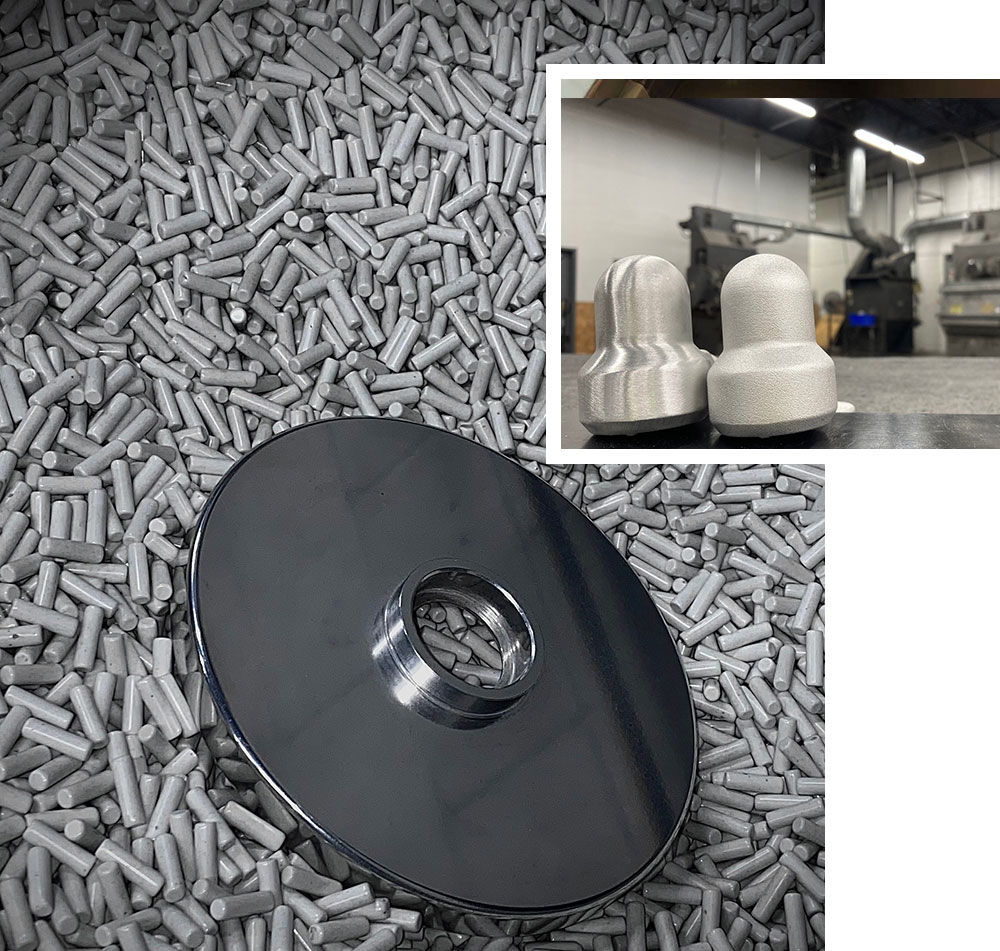

Vibratory

Vibratory finishing is a finishing process that uses different types of media to achieve desired finishing results. Vibratory finishing services are suitable for the following applications:

Hand Deburr

Hand Deburring is one of our most efficient industrial finishing services in Minnesota. The process helps remove rough and sharp edges or burrs. This finishing method is used when other techniques are not viable.

With precision hand deburring, it is possible to remove even the smallest burrs and extraneous materials. This type of finishing process works on parts with small spaces and rough drilling holes.

Here at EFI, our staff is experienced enough to offer hand deburring services in an efficient and economical way.

Get in Touch with Us

We have the dedication, experience, and expertise to offer industrial finishing solutions in Minnesota. This helps us to meet the variable demands of our customers.

If you need the best possible finishing services in Minnesota, we are the ones to trust. For further details and quotes, just get in touch with us Today!